- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Size: 210

- Place of Origin: Qingdao

- Brand Name: highfull

- Model Number: highfull

- Weight: 15000.000 kg

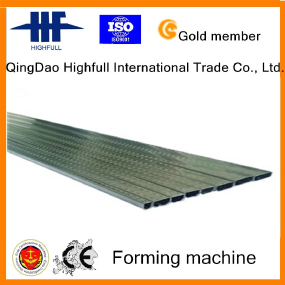

Insulated Glass aluminum spacer production line is advanced technology, superior performance, and high cost performance, production speed more 120 M/Min. The model of aluminum spacer include: 6A, 9A, 12A, 14A, 15A, 16A, 19A, 20A.

1. Aluminum spacer has been widely used in energy-saving window and door. Our chopped wave type high frequency power supply has advantage in energy-saving and reliability, some company has adopted it.

2. Process flow: Uncoiler - loading - forming - high frequency welding -scraper -sizing -straightening- flying saw -lay off table.

3. Composition of production line: Uncoiler, tube mill, solid state high frequency welder, straightening and shaping machine, flying saw.

4. High frequency welder use chopped wave type high frequency power supply, welding speed 50-180 M/Min.

5. The requirement of aluminum spacer:

A. Wall thickness: Wall thickness must between 0.2-0.35mm, the maximum deviation is± 0.025mm.

B. Curvature: Spacer should no hard bending and side bending (beside bending radian of free droop).

C. Appearance: Surface is flat and smooth, no bump, pore uniformity and orderliness.

FAQ

What is main parameters?

1.Gear box and universal joint drive.

2.PLC control.

Is the sample available?

Yes,sample are available for you to test the quality.

Are the products tested before shipping?

All the products have to pass strict inspection before they go out.

Why choose us?

1.We are a factory manufacturing ,best production capability,best quality control,best service.

2.competitive price.

3.Best after-sale service.

4.Different types of roll forming machine,customers' own design is OK.

5.Super High quality.

6.Big production ability.

What is benefit will you bring?

Your client satisfied on the quality.

Your client continued orders.

You can get good reputation from your market and obtain more orders.

3.our survices

3.1 Meeting clients' diversified requirements on machines.

3.2 High quality machine with reasonable price.

3.3Guaranteeing the quality of machine we providing.

3.4 Every process will be checked by responsible QC which insures every product's quality.

3.5 Professional packing teams which keep every packing safely.

3.6Trial order can be done in one week.

3.7Samples can be provided as your requirements.

Terms:

1. Delivery: According to customers' requirement.

2. Package: Export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after you inspect machine we need).

4. Delivery date: Within 60 working days after receiving deposit.

5. Products Warranty: 12 month, and we will provide the technical support for whole life of the equipment.

4.About us

We are professional in making roll forming machine for several years.

4.1 Delivery:in only 5-8 weeks for urgent order.

4.2 Capacity:12-15 sets /month.

4.3 Have our own tool center from raw material to the final high-precision forming machine.We have our precise tooling center.

4.4 Y ou can rely on our term!

We have engineers with experience more than 15 years in metal forming industry.

- Size: 210

- Place of Origin: Qingdao

- Brand Name: highfull

- Model Number: highfull

- Weight: 15000.000 kg

Insulated Glass aluminum spacer production line is advanced technology, superior performance, and high cost performance, production speed more 120 M/Min. The model of aluminum spacer include: 6A, 9A, 12A, 14A, 15A, 16A, 19A, 20A.

1. Aluminum spacer has been widely used in energy-saving window and door. Our chopped wave type high frequency power supply has advantage in energy-saving and reliability, some company has adopted it.

2. Process flow: Uncoiler - loading - forming - high frequency welding -scraper -sizing -straightening- flying saw -lay off table.

3. Composition of production line: Uncoiler, tube mill, solid state high frequency welder, straightening and shaping machine, flying saw.

4. High frequency welder use chopped wave type high frequency power supply, welding speed 50-180 M/Min.

5. The requirement of aluminum spacer:

A. Wall thickness: Wall thickness must between 0.2-0.35mm, the maximum deviation is± 0.025mm.

B. Curvature: Spacer should no hard bending and side bending (beside bending radian of free droop).

C. Appearance: Surface is flat and smooth, no bump, pore uniformity and orderliness.

FAQ

What is main parameters?

1.Gear box and universal joint drive.

2.PLC control.

Is the sample available?

Yes,sample are available for you to test the quality.

Are the products tested before shipping?

All the products have to pass strict inspection before they go out.

Why choose us?

1.We are a factory manufacturing ,best production capability,best quality control,best service.

2.competitive price.

3.Best after-sale service.

4.Different types of roll forming machine,customers' own design is OK.

5.Super High quality.

6.Big production ability.

What is benefit will you bring?

Your client satisfied on the quality.

Your client continued orders.

You can get good reputation from your market and obtain more orders.

3.our survices

3.1 Meeting clients' diversified requirements on machines.

3.2 High quality machine with reasonable price.

3.3Guaranteeing the quality of machine we providing.

3.4 Every process will be checked by responsible QC which insures every product's quality.

3.5 Professional packing teams which keep every packing safely.

3.6Trial order can be done in one week.

3.7Samples can be provided as your requirements.

Terms:

1. Delivery: According to customers' requirement.

2. Package: Export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after you inspect machine we need).

4. Delivery date: Within 60 working days after receiving deposit.

5. Products Warranty: 12 month, and we will provide the technical support for whole life of the equipment.

4.About us

We are professional in making roll forming machine for several years.

4.1 Delivery:in only 5-8 weeks for urgent order.

4.2 Capacity:12-15 sets /month.

4.3 Have our own tool center from raw material to the final high-precision forming machine.We have our precise tooling center.

4.4 Y ou can rely on our term!

We have engineers with experience more than 15 years in metal forming industry.